SA.G.E.M. SRL

Rotomoulding Division

Application Field

- AGRICULTURAL

- FOOD

- FURNITURE

- AUTOMOTIVE

- CHEMIST

- CONTAINERS

- ECOLOGICAL

- BUILDING

- GARDENING

- TOYS

- WATER

- NAUTICAL

- ROAD

- SANITARY

- SPORTY

Rotomolding plant for various product

Our History

The approach of SA.G.E.M. SRL in the world of rotational molding, takes place in 2002 thanks to one of our customers who decided to expand his production activity in the plastic sector, bought a used rotational plant and asked us to completely regenerate it. That was our test bed that made us acquire the first skills and insights on how to improve the car.

We began to build the first complete machines for some Italian manufacturers and printers and for others we only built the arms, improving their mechanical reliability.

Today we want to extend our experience to the whole world market, guaranteeing: a high quality Italian product in compliance with EC directives 2006/42 / EC; 2014/35 / EC; EMC2014 / 30 / CE; seriousness and maximum after-sales assistance.

Our machines are updated with new mechanical and thermal solutions such as the oven, in which we also used ceramic fiber panels, and with the application of high-performance burners. The electrical system has been revised by applying the latest technological solutions on the market today.

We are at vs. provision to retrofit and solve problems on existing machines; our warehouse has a wide range of mechanical spare parts such as gears, shafts, headsconcerning the arms and burners; We also guarantee electrical interventions up to the PLC and its software, also improving its operation.

We can also supply used plants, scrupulously overhauled in all its parts,

We build machines of all sizes from small up to with spherical dimensions of 6200 mm. The complete machines built to date, they are located both in Italy and abroad, divided into various configurations: Carousell, Sway and Shuttle,

Plants

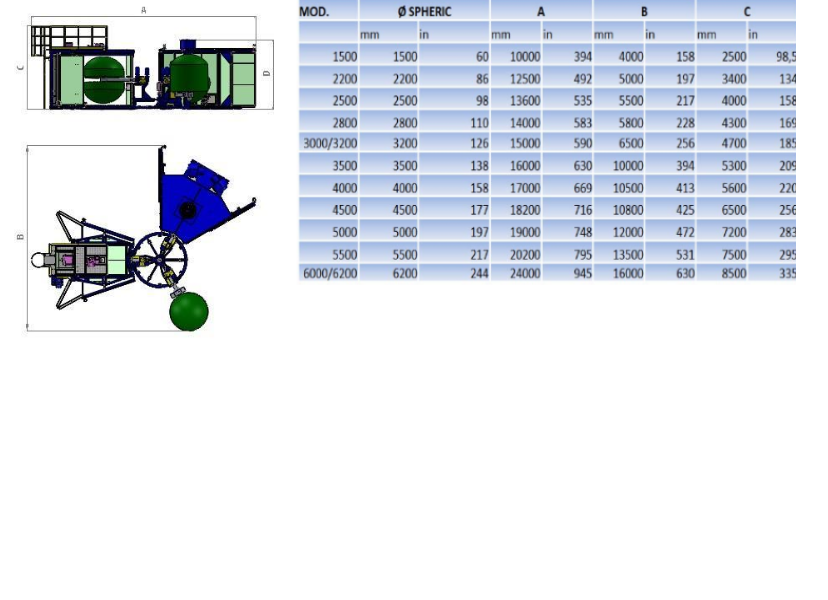

CAROUSEL

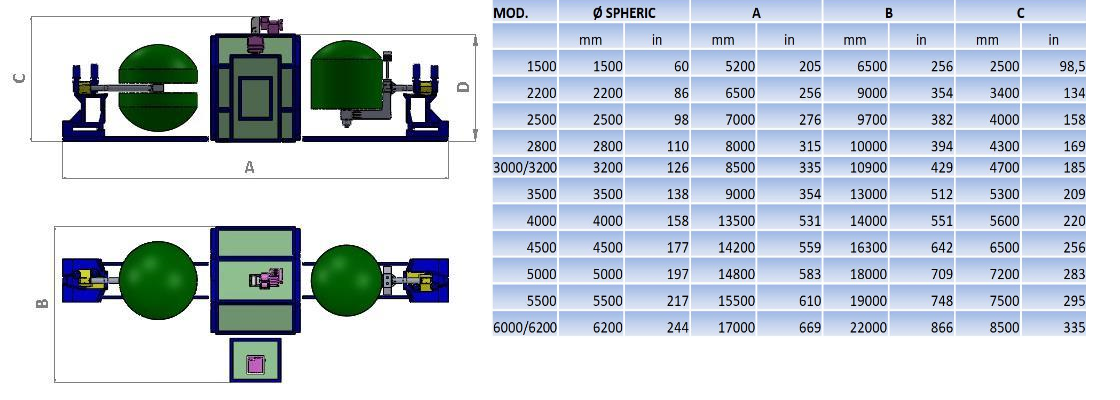

SHUTTLE

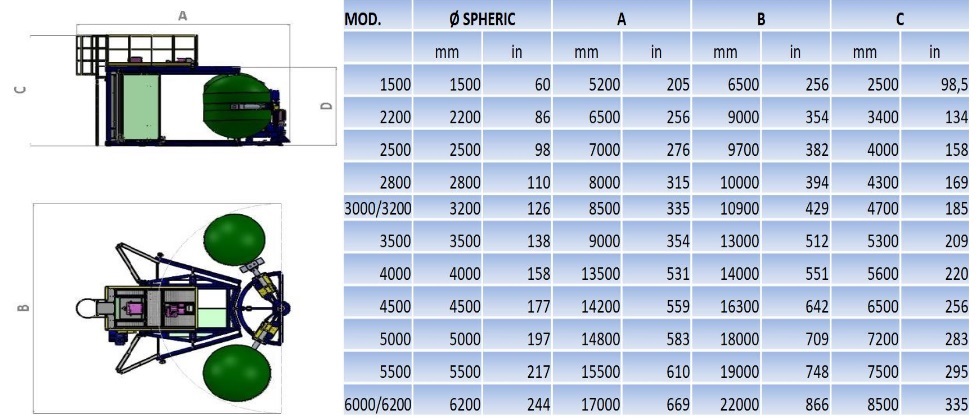

SWAY

Carousel

Solidity, reliability and simplicity are the essential characteristics that we put in our machines.

Optimal machine for large volumes of work with molds organized with similar recipes.

The machine consists of:

- Oven With high insulating power

- Modulating burner with control to optimize combustion

- independent trolleys on which straight or square arms are positioned with the possibility of interchangeability

- Electric panel with Touch-screen for the complete management of the machine

- Safety barriers with acoustic alarms

- Cooling chamber with high efficiency fans using nebulized water

- External console for use in loading, unloading and setting operations

- teleservice

The machine is configured up to a maximum of 6 work stations

Optional:

- Work platform

- Internal cooling chamber in stainless steel

Configuration :

The rotary column in the center of the machine is the fulcrum of the system, on which the trolleys rotate with the relative arms applied that accompany the mold in the working positions: loading / unloading, oven, cooling. all controlled by a new, very intuitive and easy to use software.

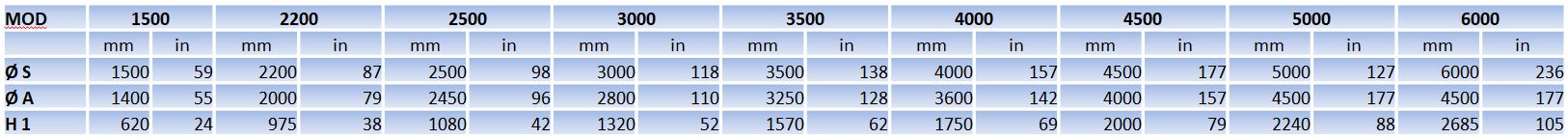

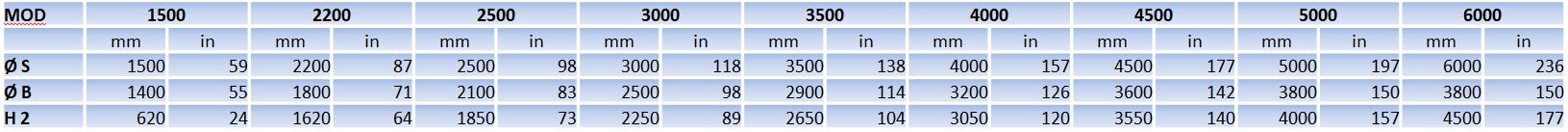

CAUTION The dimensions indicated are purely indicative.

Shuttle

This machine is suitable for the production of large or medium-sized parts with different cycle characteristics.

The machine normally works in line by alternately introducing the trolleys into the oven which has two opposite doors.

The machine consists of:

- OVEN With high insulating power

- Modulating burner with control to optimize combustion

- independent trolleys on which straight or square arms are positioned with the possibility of interchangeability

- electrical panel with Touch-screen for complete machine management

- Safety barriers with acoustic alarms

- N. 2 external console for use of loading, unloading and set operations.

- Teleservice

Optional:

Work platform

Configuration :

The oven is located in the center of the machine with respect to the trolleys positioned on the sides.

The rest position of the trolley acts as a loading / unloading / cooling and waiting area.

CAUTION The dimensions indicated are purely indicative.

Sway

The SWAY version has the same functionality as the SHUTTLE version, only it is seen on a half version of the CAROUSEL and therefore allows different cycles without compromising the production, but at the same time allows a future transformation into the CAROUSEL system to increase productivity

The machine consists of:

- Oven With high insulating power

- Modulating burner with control to optimize combustion

- independent trolleys on which straight or square arms are positioned with the possibility of interchangeability

- Electric panel with Touch-screen for the complete management of the machine

- Safety barriers with acoustic alarms

- External console for use in loading, unloading and setting operations

- Teleservice

The machine is configured up to a maximum of 6 workstations

Optional:

Work platform

Configuration :

The rotary column in the center of the machine is the fulcrum of the system, on which the trolleys rotate with the relative arms applied that accompany the mold in the working positions: loading / unloading, oven, cooling. all controlled by a new very intuitive and easy to use software

CAUTION The dimensions indicated are purely indicative.

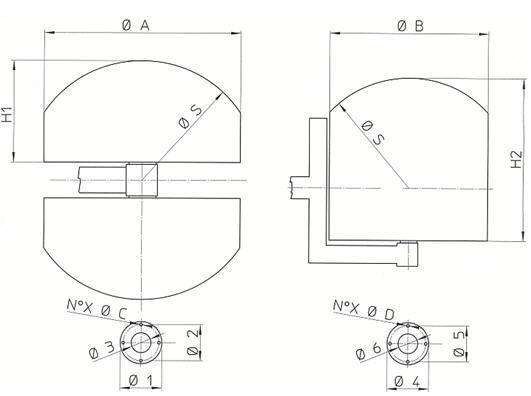

ALLOWABLE DIMENSIONS ON THE ARMS FOR MOLDS APPLICATION

STRAIGHT ARM

OFF SET ARM

The dimensions of the square arm can be customized according to the customer’s needs

OFF SET ARM

Indispensable for the production of large items using all the available space.

This arm has a large load capacity and a lot of strength with little maintenance.

The rotation comes through gear and chain system

The arm is balanced by means of adjustable counterweights, included in the supply

To convey the air to particular areas of the mold, it’s possible to fit from 2 to more airways at high and low pressure and the Venturi tubes

C ARM

Indispensable for the production of very large items, where the support of the mold is required on both sides

It has the same characteristics as the square arm, but having two support points for the mold, the C arm is able to guarantee a greater capacity in complete safety.

PLATFORM

Fixed or mobile, it is used to facilitate and speed up the mould opening / closing operations, extraction of the finished product , raw material handling.

SPIDER

Spider, essential for fixing multiple molds and producing multiple products at the same time.

They are produced according to customer needs

360° Assistence service

- Retrofitting on used plants,

- Arms revision,

- Head revision,

- Mechanical spare parts such as shafts, gears, heads etc…

- Electric / electronic spare parts, speed variators, motors, solenoid valves, thermocouples, burners, fans, PLC, etc….

- Teleservice

- Plants used

Scegli la lingua e compila il form per ricevere il catalogo

[contact-form-7 404 "Not Found"]

DOWNLOAD CATALOG